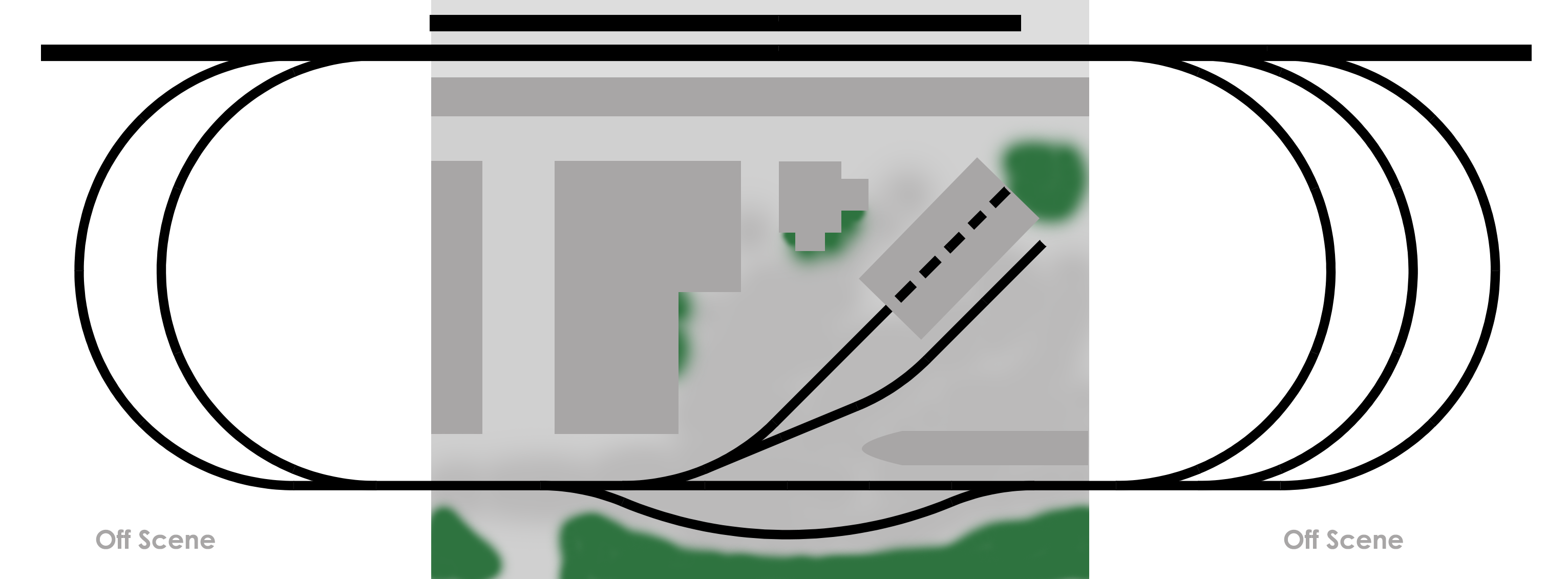

Bond Lane is largely recycled from a previous exhibition we made but that never saw the light of day for a number of reasons. Most of the metcalfe buildings and the viaduct were built for that layout, as was the folding case. The original layout was around a third longer, but not as deep. Thankfully the way we built it allowed us to adopt it relatively easily.

When the layout is folded it has only a third the footprint of when it is full unfurled which has obvious advantages both for storage and transportation - allowing the layout to fit easily into the boot of our car for example. There were two challenges to overcome to make this happen.

Because the layout is a box rather than a flat layout, simply putting hinges between the two parts of the baseboard wouldn't work because the end piece would only be able to fold through 90 degrees (or probably a bit less with the track in the way). The solution to this was to have extra pieces of wood the height of the case, connected top and bottom and cut in half with the hinges then joining it back in the middle. This puts the pivot point exactly where it needs to be for the side pieces to fold up and rest on top of the layout. There is a slight difference in where the wood was cut on one side to the other so that the one side sits on top of the other when folded.

In terms of wiring, any wires that need to be run to the end section just need to be run along the vertical posts with the hinges on. The length of the wire required remains the same all all times, so they neither get stretched or end up loose and likely to get snagged.

The remaining challenge was getting the tracks to line up both horizontally and vertically with each other. Vertically was relatively easy, the baseboards are the same thickness all the way through, so adding a couple of blocks of wood to sandwich them from above, with the desk below ensures everything lines up. On the fold down sections, the track is mounted on a piece of plywood that is not fixed. Using a slot in the lower baseboard to keep it attached. This allows the whole section to be adjusted in all directions to make sure it is lined up.

The amount of wood we used to achieve all this does mean it is just too heavy for one person to lift. The entire base is double thickness plywood, as is the top of the central section.

by Neil Limbrick

661 views

70 days ago

by Neil Limbrick

3753 views

2 years ago

by Neil Limbrick

2760 views

2 years ago

by Neil Limbrick

2371 views

2 years ago

by Neil Limbrick

2058 views

2 years ago